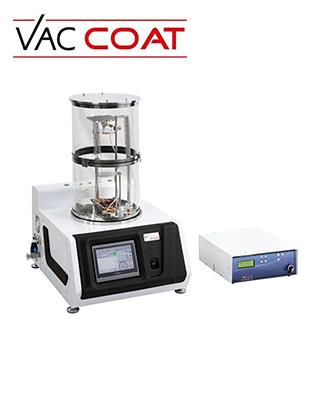

桌上型碳塗佈機

| 台式碳塗佈機 - DCR 是一種緊湊型碳纖維塗層系統,適用於掃描電子顯微鏡 (SEM)、穿透式電子顯微鏡 (TEM) 和 X 射線分析 (EDX) 中的樣品製備。 | |||||||||

|

台式碳塗佈機 - DCR 的特點

|

|||||||||

|

脈衝碳纖維蒸鍍 台式真空碳塗佈系統 - DCR 能夠進行脈衝碳纖維蒸鍍。短脈衝可提供更有效掌控的沉積狀態,並顯著減少與傳統碳沉積相關的碎屑量。 |

|||||||||

|

|||||||||

|

|||||||||

- Two-stage, direct drive 4 m3/h, rotary vane pump

- Ultimate vacuum: Less than 50 mtorr

- 170 mm OD x 140 mm pyrex cylinder chamber

- 0-25A switching pulsed DC power supply

- Dimensions: 450 x 500 x 370 mm(H x W x D)

- Utilities: 220V-240V, 50/60HZ, 10A

- Rotational sample holder with adjustable tilt and height

- Sample holder with planetary rotation (Optional)

- Electronic shutter

- Manual or full automatic control

- Precision electronic leak valve for fine control of vacuum pressure

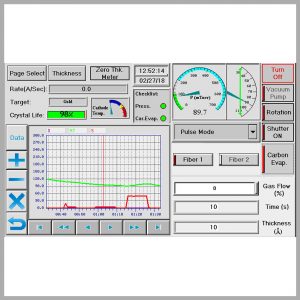

- Real time plots of coating parameters

- Simple transfer of coating data plots via USB port to PC

- Shipping weight: 46 Kg

- Plasma Cleaning

Options and Accessories

The Carbon Coating System has following options and accessories:

- Quartz crystal sensor

- Sample Planetary Rotation System (optional)

- Spare vacuum glass cylindrical chamber

- Carbon fiber

- Sealing gaskets

| Desk Carbon Coater – DCR is a compact carbon fiber coating system suitable for Sample Preparation for the use in scanning electron microscope (SEM), transmission electron microscope (TEM), and X-Ray analysis (EDX). | |||||||||

|

Features of Desk Carbon Coater – DCR

|

|||||||||

|

Pulsed Carbon Fiber Evaporation The desk vacuum carbon coating system – DCR is able to perform pulsed carbon fiber evaporation. Short pulses provide more controlled deposition and significantly reduces the amount of debris associated with traditional carbon deposition. |

|||||||||

|

|||||||||

|

|||||||||

- Two-stage, direct drive 4 m3/h, rotary vane pump

- Ultimate vacuum: Less than 50 mtorr

- 170 mm OD x 140 mm pyrex cylinder chamber

- 0-25A switching pulsed DC power supply

- Dimensions: 450 x 500 x 370 mm(H x W x D)

- Utilities: 220V-240V, 50/60HZ, 10A

- Rotational sample holder with adjustable tilt and height

- Sample holder with planetary rotation (Optional)

- Electronic shutter

- Manual or full automatic control

- Precision electronic leak valve for fine control of vacuum pressure

- Real time plots of coating parameters

- Simple transfer of coating data plots via USB port to PC

- Shipping weight: 46 Kg

- Plasma Cleaning

Options and Accessories

The Carbon Coating System has following options and accessories:

- Quartz crystal sensor

- Sample Planetary Rotation System (optional)

- Spare vacuum glass cylindrical chamber

- Carbon fiber

- Sealing gaskets